Services

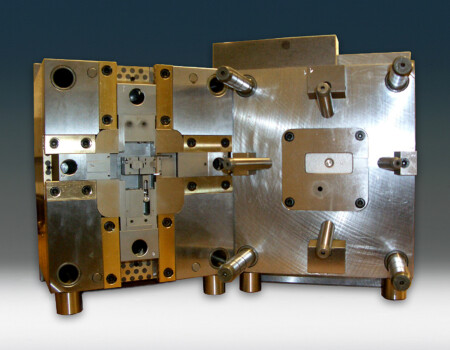

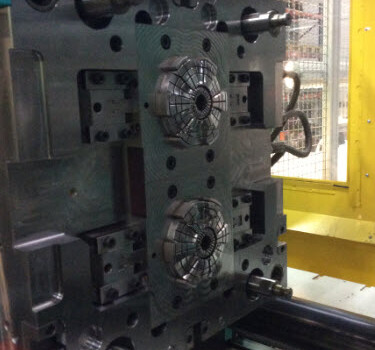

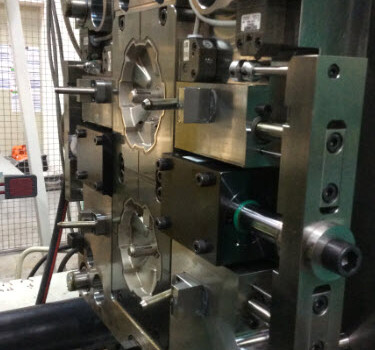

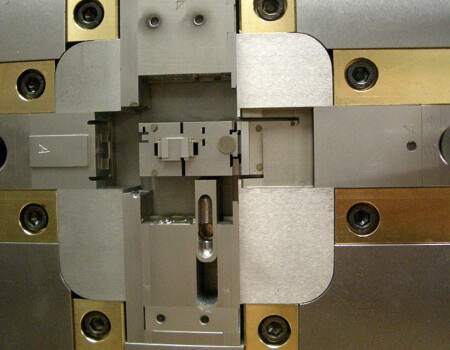

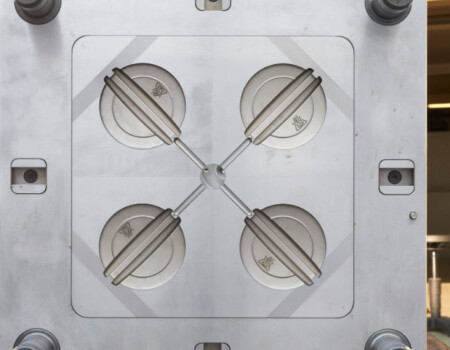

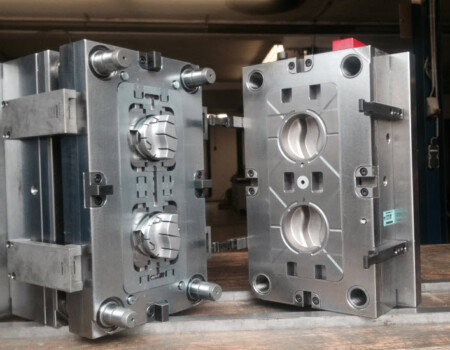

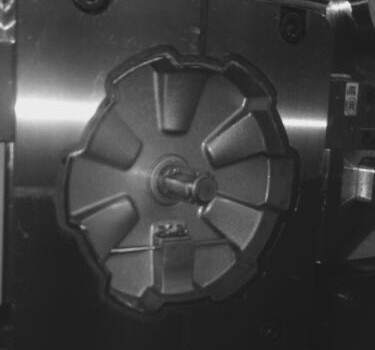

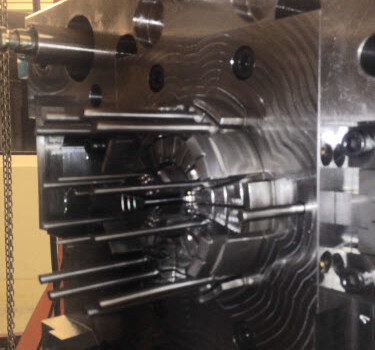

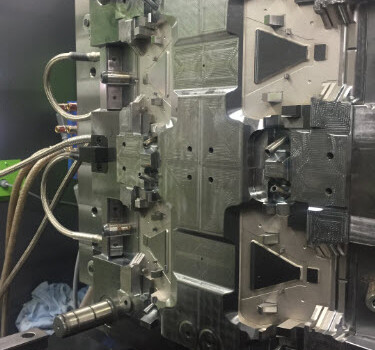

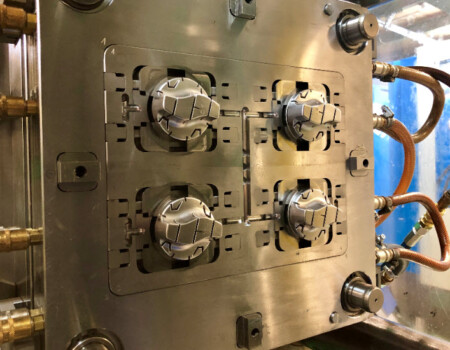

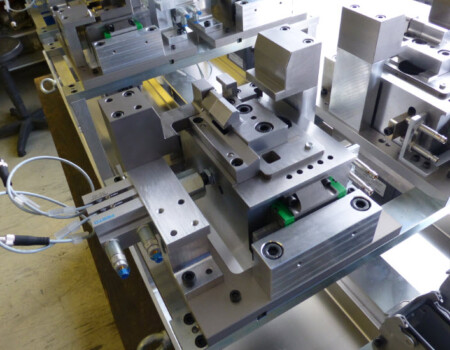

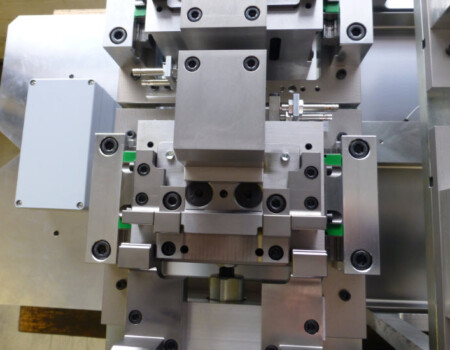

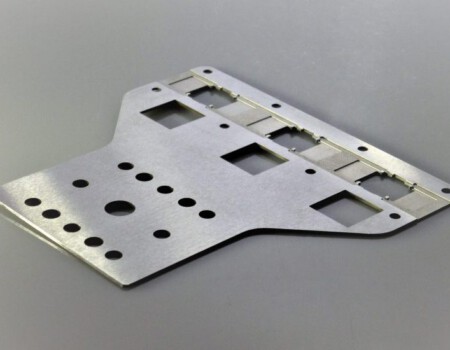

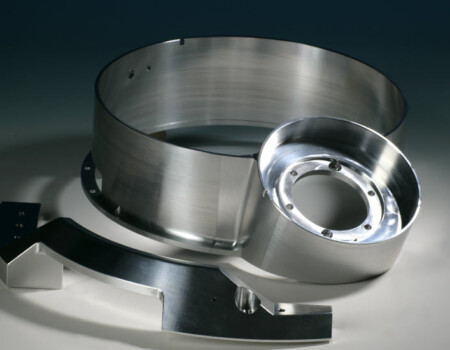

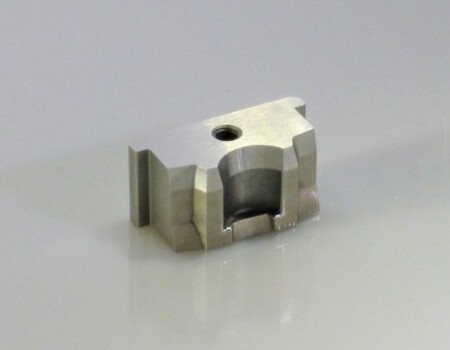

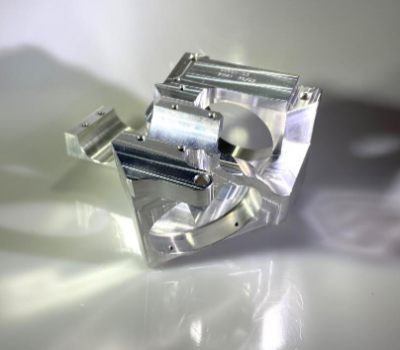

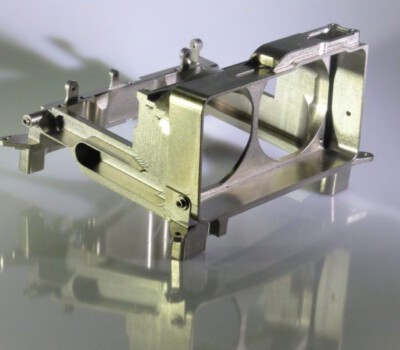

Especially in the field of mould and tool making RGF follows the maxim “…highest precision down to the smallest detail…”. For us the decisive factor for achieving this objective is an optimum tool design tailored to your needs, if required also with filling and distortion analyses. A modular construction allows for a rapid procurement of wear and replacement parts based on the bill of materials, which results in minimum downtimes.

Further factors of success are our modern, state-of-the-art machinery, sophisticated and optimized manufacturing processes and in particular the experience and competence of our employees!

Taken together, they form the basis for our very high quality level and sustainably produced precision. Due to the parallel, consequent orientation towards economic variables, such as the optimization of lead times, and a high degree of standardisation and automation, we turn the projects of our customers into real success stories.

We also carry out sampling and prepare initial sample test reports for you. We provide you with a tool that is suitable for series production including all technical documentations.

We would be glad to manufacture the following tools for you:

- Sliding core moulds

- Unscrewing moulds

- Sliding split moulds (also hydraulic)

- Multi-plate moulds

- Hot runner moulds

- Multi-component moulds

Or as in most cases: a varied combination of the above-mentioned moulds.

Put us to the test and benefit from our many years of experience!

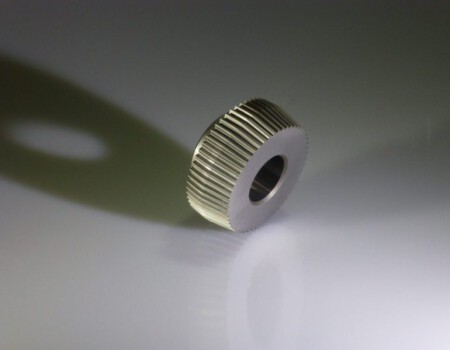

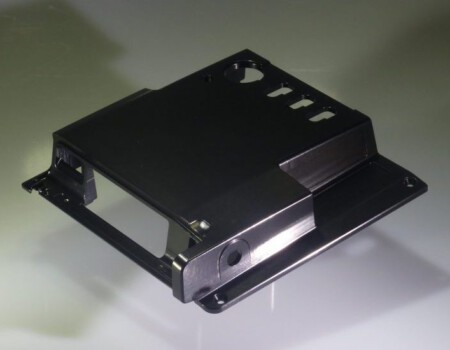

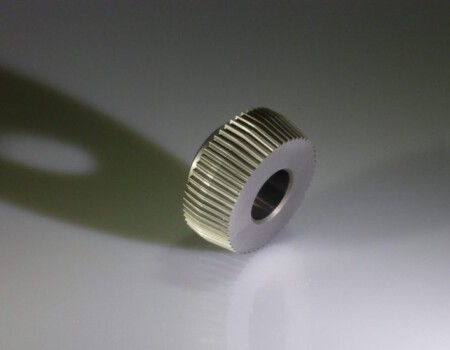

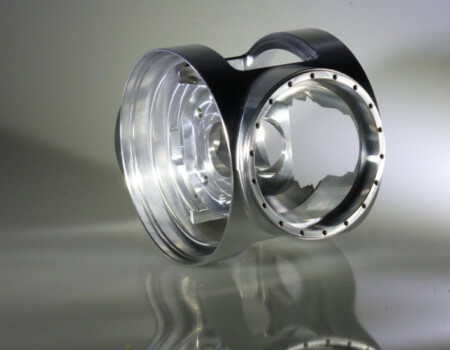

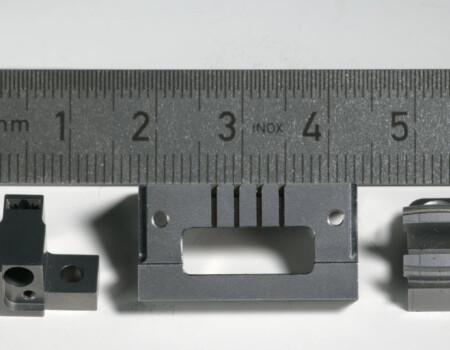

Being an owner-operated company with many years of experience in the production of first-class high-precision parts, we know exactly what it takes. With the help of our ultra-modern CNC machines and the experience of our employees who are willing to learn every day and to “think outside the box”, we give the term “precision part” a completely new meaning.

Another major advantage is also our extensive machinery with the so-called ”niche technologies” wire-cut EDM and sinker EDM. Since we do not need the assistance of sub-contractors in this field, we here act true to the motto:

„Action is better than reaction“.

If it is about the economic manufacturing of demanding geometries, be it in the small or medium series range, we are at your side as a competent and reliable partner. You as our customers are in the focus of all our actions, because your satisfaction is part of our reward and our most important reference!

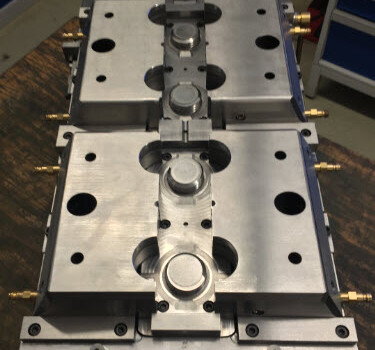

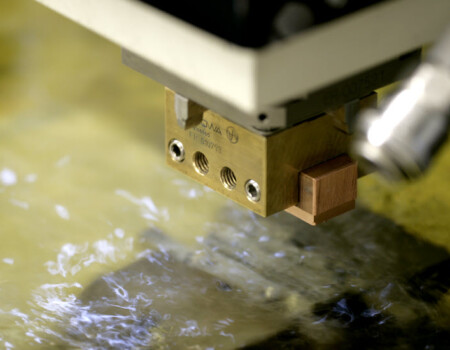

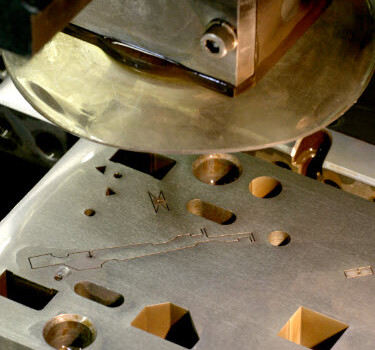

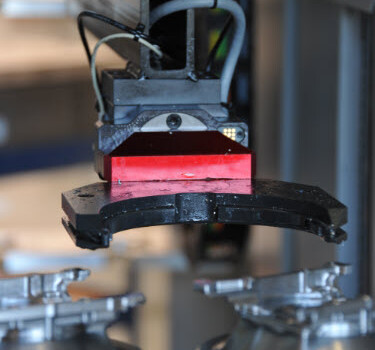

We at RGF can offer you our service electrical discharge machining in the fields of wire-cut EDM and sinker EDM as well as EDM hole drilling.

All machines are connected to a central DNC server that provides them with CNC programs. These programmes are created by our programmers using advanced CAD/CAM software.

The key points of our EDM department:

- 24-h services due to a flexible working time model

- All machines are equipped with the same CNC control

- Central job management

- Extensive range of versatile clamping tools for almost all applications

- Large stock of already hardened EDM blocks made of steel and cemented carbide

Equipment

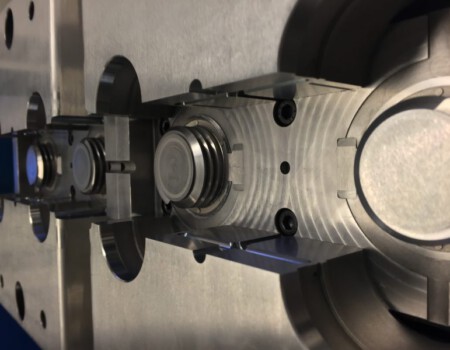

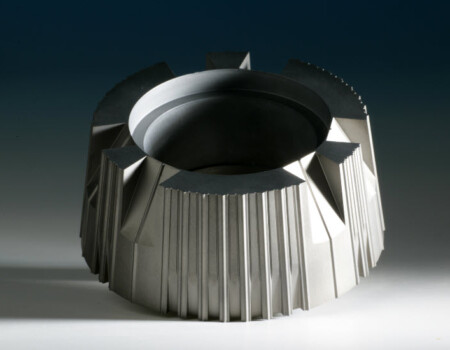

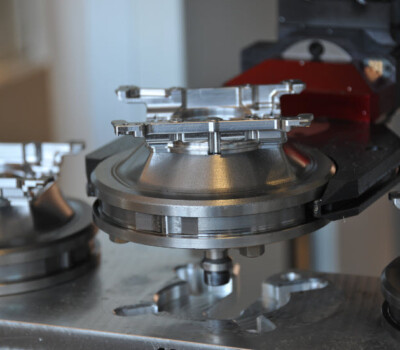

Generally we at RGF differentiate between 3-axis milling and 5-axis milling. We possess modern, state-of-the-art machinery and can professionally employ both techniques depending on your requirements and tasks.

The key points of milling:

- All machines are equipped with the same CNC control and connected to a central DNC server

- Central tool management

- Extensive range of holders with highly precise shrink technology

- Professional use of the 5-axis simultaneous technology

- All machines have the same high-quality equipment: 3D infrared touch probe, measuring laser, tool changer, and automatic chip removal

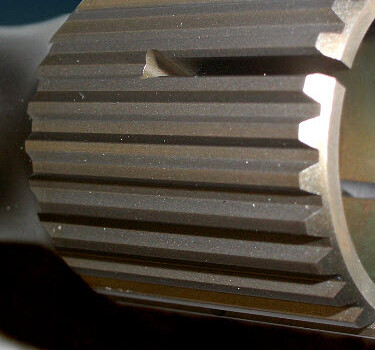

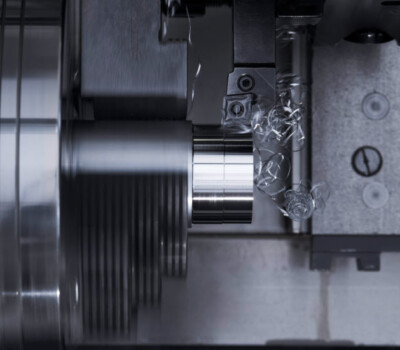

The combination of modern CNC technology and technically mature lathes enables us to manufacture precision parts that are accurate down to the smallest detail.

Regardless of whether it is single or serial parts, we are your competent contact in the processing of machinable materials!

One of the historical core competences of the company RGF is the field of electrical discharge machining.

Every day we work out new solutions for the complex tasks of our customers. This specific know how is expanded and perfected not least due to our long-standing experience and the in-depth knowledge of the company’s founder as well as the consequent training and further education of our employees.

From the very beginning we have successfully employed EDM technology, which originates from tool making, also in the series production of precision parts.

RGF offers its customers services in the field of „surface, cylindrical and profile grinding“. In the field of CNC surface and profile grinding we are capable of profiling the grinding wheel with almost any desired contour.

This offers our customers the advantage that highest repeat accuracy in geometry and surface can be achieved over the entire grinding area.

Grinding disks that are suitable for almost all materials are available. In addition, RGF possesses extensive equipment for polishing, honing and lapping of metals and cemented carbides; high-gloss polishing is also possible.

At RGF we create 3D-constructions, 2D-drawings as well as the CAD programming of all CNC machines with the software “Pictures by PC2” by Schott Systeme. Furthermore, we are capable of applying a plurality of CAD formats of our customers.

Programming work is carried out in separate offices by highly trained specialists. From there the programmes are transmitted via a central DNC server to the corresponding machine control systems. In total 6 working places are available.

Since we are well-versed in using the 5-axis simultaneous technology, we are able to implement even the most difficult geometries in complex CNC programs which only require short production times in the machining centres.

RGF employs the CAD/CAM software “Pictures by PC”

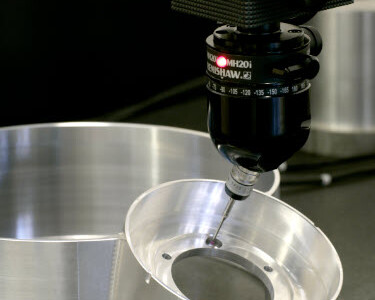

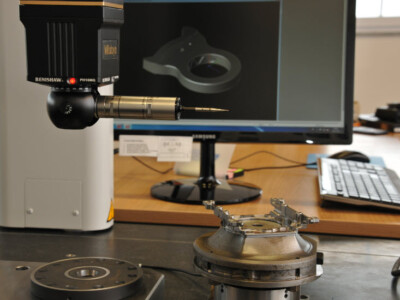

The field measurement technology completes our wide range of services.

At RGF we do not only generate precision, we also submit evidence for it… since highest precision can especially be seen in the individual details! Therefore all parts manufactured by us are completely measured, checked and documented according to preset quality control plans.

For this purpose an air-conditioned measuring room with extensive measuring and testing equipment is available.